Never losing connection

2020 has been a dynamic year for many industries. The global pandemic has tested our connections to each other and often forced us to keep a safe distance. Still, at TTTech we have found a way of handling the current situation that works well for our business, our company and our employees.

Despite all challenges, the TTTech Group is facing the future with confidence Watch this video to see our progress in numbers:

TTTech Group: growth through knowledge and collaboration

In 2020, the TTTech Group has welcomed around 450 new employees for a team that now exceeds 2,300. We have also opened three new offices, in Barcelona, Izmir and Houston. Our strong brand image was recognized with the Busines Superbrands Austria Award 2020.

Throughout the year, the TTTech Group was active in 36 research projects, including the EU-funded projects Productive 4.0, UP2DATE and many more. Our strong involvement in research and development has found international recognition: TTTech’s success story was credited by the ECSEL JU and TTTech Labs researcher Silviu Craciunas won Best Paper at ETFA 2020 in collaboration with Denmark Technical University.

TTTech Auto expanded its global footprint and business

2020 was the starting point for TTTech Auto’s Car.OS business. The adapted structure at year-end is based on three distinct pillars: a scaled-up customer programs unit, a dedicated product development unit and a newly set-up Car.OS unit. The Car.OS unit aims to develop a best-in-class car operating system and will build up an ecosystem with different partners to enable seamless development for customers.

As part of its overall growth strategy, TTTech Auto acquired the Izmir-based automotive company Red Pine Software. The 60 employees are experts in automotive embedded software engineering with a focus on ADAS. In spring, the company opened a development office in Madrid in addition to the Barcelona office to further reinforce their development capacities for global customer projects.

TTTech Auto increased the number of its workforce by about 40% to about 1,200 employees in September 2020.

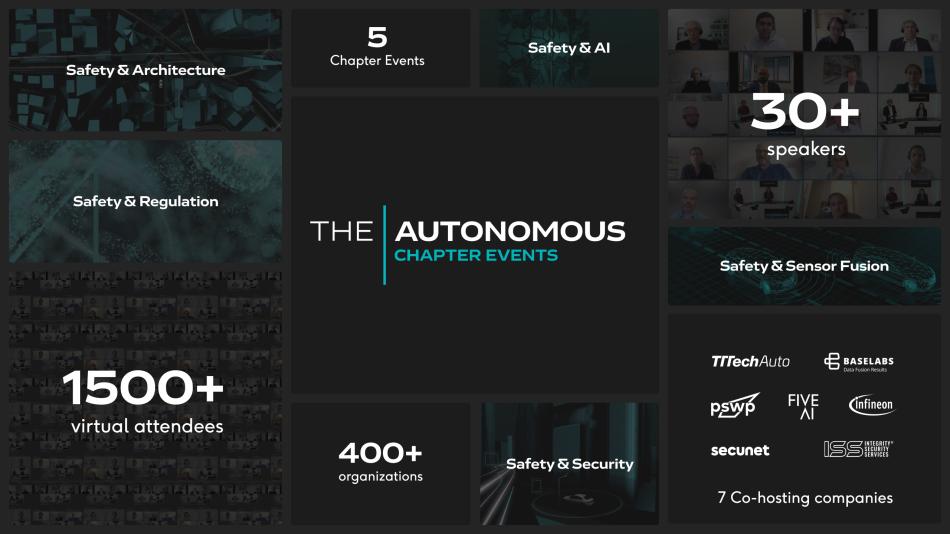

The Autonomous is growing the community of safe autonomous mobility

The Autonomous, the global community shaping the future of safe autonomous mobility, assembled 1,500 technical experts from over 400 international organizations in five virtual Chapter Events on key challenges in autonomous driving. Each Chapter Event included presentations by well-known industry experts followed by interactive, virtual Q&A sessions, panel discussions as well as a survey conducted among international participants. The tackled challenges involved the overall aspect of safety in combination with architecture, AI, security, regulation, and sensor fusion topics.

The findings of the Chapter Events will be presented at The Autonomous Main Event on September 29, 2021. These findings will serve as the basis for further collaboration and continued work towards global reference solutions for safe autonomous mobility.

TTControl customers benefit from state-of-the-art technology and safety

TTControl announced the global product launch of Vision 3. This latest display generation by TTControl is designed to be in the center of complex vehicle system architectures due to the extensive electronic possibilities it offers. Since the first presentation of Vision 3 in 2019, multiple feedback from prototype users had been collected. The result is the launched mature, state-of-the-art display tailored for the high requirements of a global customer base in the off-highway industry.

Australian-based haulage truck company Loadpro shows what a display must be able to achieve even in the harshest of environments on the example of the eVision² 10.4 display.

TTControl’s controller family certification for road use under ISO 26262:2018 allows the validation on component level. This can help to clearly reduce development costs as stated by TTControl Managing Director Manfred Prammer in a guest commentary at ATZelectronics worldwide. Furthermore, the certification allows the use of the TTC 500 electronic controllers in road vehicle electrical and electronic (E/E) systems for the first time.

Rosenbauer, a world-leading firetruck manufacturer, directly benefits from the now safety certified electronic controllers. Two TTC 580 safety controllers ensure functional safety also in critical situations of the Rosenbauer RT (abbreviation for ‘Revolutionary Technology’), the first hybrid electrified fire fighting vehicle.

TTTech Industrial expands its solutions for Industry 4.0 and smart manufacturing

In 2020, TTTech Industrial received the ISO 9001 certification for the development of real-time communication solutions and open computing platforms for the industrial Internet of Things.

Machine and plant engineering company Fill used TTTech Industrial’s edge computing software Nerve Blue to enable high-performance data access in real-time and to reliably connect machines worldwide. As the software runs on any standard industrial PC with an Intel Atom processor or upwards, it allows customers to leverage existing hardware installations to save time and cost. A new service for those getting started with edge computing and digitalization projects is the free trial of Nerve Blue. Users gain access to an online sandbox where they can easily familiarize themselves with the features of Nerve Blue. The free trial requires no hardware set-up or software installation. In December, the Linux Foundation announced that the latest version of their ACRNTM hypervisor is now included in Nerve Blue. TTTech Industrial and Intel are active participants in the ACRN project and have contributed to shaping the technology. Nerve Blue is the first commercial product for the industrial market based on ACRN.

TTTech Industrial enabled further applications for smart manufacturing with comprehensive TSN implementation. Automation company B&R partnered with TTTech Industrial to become the first company to offer a complete OPC UA over TSN industrial automation product line significantly reducing their development time for the network part. In November, TTTech Industrial introduced a comprehensive starter package for building, configuring and testing TSN networks. It enables maximum configuration flexibility for customers and is offered in three variants to suit every evaluation project.

Further Industry 4.0 projects include the collaboration with local innovation hub Swiss Smart Factory. In this project, Nerve Blue is installed in the demo plant and showcased in a real manufacturing environment in different use cases. The continued partnership with Intel was also highlighted in a robotics control demo that shows one of many potential use cases for Nerve Blue.

Aerospace applications ready for takeoff

TTTech’s business unit Aerospace was very active in the space sector in 2020, working on several projects with large contractors. TTTech also announced the appointment of space executive Bob Richards as Vice President Space. Together with a team of experts, he supports NASA’s Johnson Space Center as well as U.S. prime contractors involved in cislunar and lunar surface exploration from the newly opened office and development lab in Houston, Texas.

In July, the 6th generation Deterministic Ethernet switch for aerospace laboratory applications was released. It is already being used by several customers and offers a fast, straight-forward way to a certifiable flight switch and network solution for fault-tolerant, real-time communication in safety-related systems.