Change2Twin - Create and Harvest Offerings to support Manufacturing SMEs to become Digital Twin Champions

Project Description

The main ambition of Change2Twin is to ensure that 100% of manufacturing companies, especially SMEs and Mid-caps in Europe have access to 100% of technologies needed to deploy a digital twin.

Specifically, the project focuses on three sub-objectives:

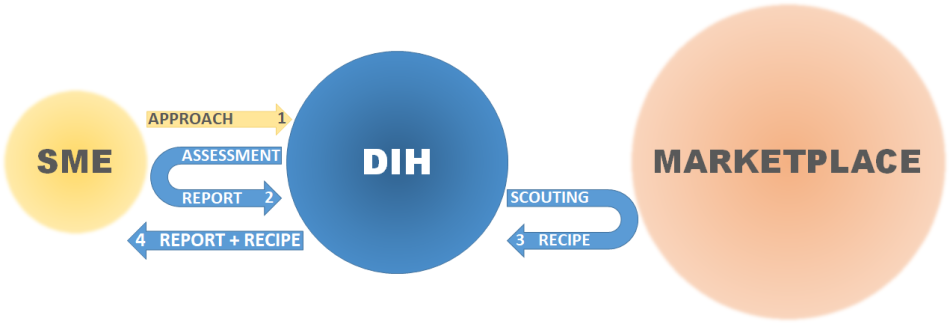

- Developing and providing a truly end-to-end service to the manufacturing SMEs where the end user receives from its local, trusted party (e.g. a DIH) a thorough analysis of the digitalization potential and a cross-border, multi-stakeholder (involving both components providers and an integrator), and ready-to-use recipe for implementation.

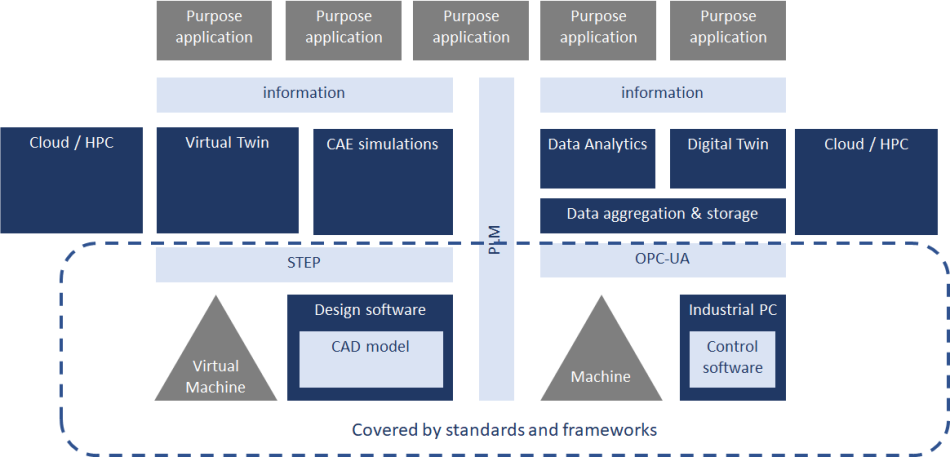

- Providing an architecture-agnostic technology marketplace with dedicated knowledge models supporting the entity preparing the recipe for a complete solution in selecting the best components and most suitable providers.

- Taking one step back to see the bigger picture and to find the minimal interoperable model facilitating modularity, composability and interchangeability of components used, regardless of the individual architectures or frameworks.

Change2Twin will deliver:

- A new benchmarked service model facilitating DIHs in providing support to manufacturing companies.

- A Pan-European marketplace populated with the state-of-the-art service providers that create coverage for end-to-end Digital Twinning solutions.

- A growing network of DIHs that have adopted the service model and marketplace based on a sustainable business model.

- An open, widely available toolbox for establishing a new marketplace consisting of software and body of knowledge gathered during the project.

- 4 Pilots proving the concept and 2 Open Calls for application experiments with a selection and support program.

Change2Twin has received funding from the European Union’s Horizon 2020 Research and Innovation program under grant agreement No 951956.

TTTech Industrial Automation contributes to the project by providing the Edge Computing platform for collecting real-time data from the machine or industrial line and by implementing it in several pilots to demonstrate its capability to support the deployment of Digital Twin.

Additionally, TTTech Computertechnik AG participates in the project as responsible partner for communication, dissemination and exploitation activities. TTTech contributes to define the content curation strategy that will be used for online dissemination to the digital community, e.g. webinars, and to coordinate specific activities such as supportive partners mapping and ambassador program.